Time to regain my printing momentum! Since I've started working with my letterpress, I've run into different problems with each project. Not enough ink, too much packing, not enough pressure, too large of design... I look at the help forums online and all the old scrooges, who have been running presses for years, say letterpress is an exact science. They insist very sternly that there is no room for trial/error. I do not listen to a word they say. Sure, if someone has a quick solution for a problem I've come across, I'm all ears. But I'm also not afraid to get a little grease on my hands tweaking things 'a little to the left/a little to the right' until I figure it out on my own, either.

So... just when I was just barely starting to figure out magnesium plates, I decided to switch over to photopolymer where I look forward to a whole new set of troubleshooting to fake my way through! Photopolymer plates are less expensive per square-inch after the initial purchase of the base. They are also better for the planet, since they can be recycled easily after you are done using them. I have the same method of design and file setup for either one, so I thought I'd give it a go.

Here are what the plates look like (this is for a set of 4 note-card designs and a business card 3-up).

They come on one big pre-adhesived sheet, and I cut each one to it's own printing plate with an exact-o knife.

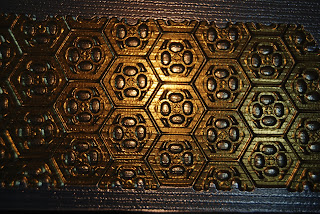

Here's a close-up with light coming in behind it. They're kind of pretty... Not sure what the reasoning behind the honey-gold color is, but I like it.

Hello , Blogger

ReplyDeleteYour blog published on Wood business cards that is nice able style .I got various tips greatly by this your blog . Truly , I supported your blog. So , I like it . Are you going to build a new business? Need business cards? Get more information for best price.

Thank you very much for your fantastic Blog .